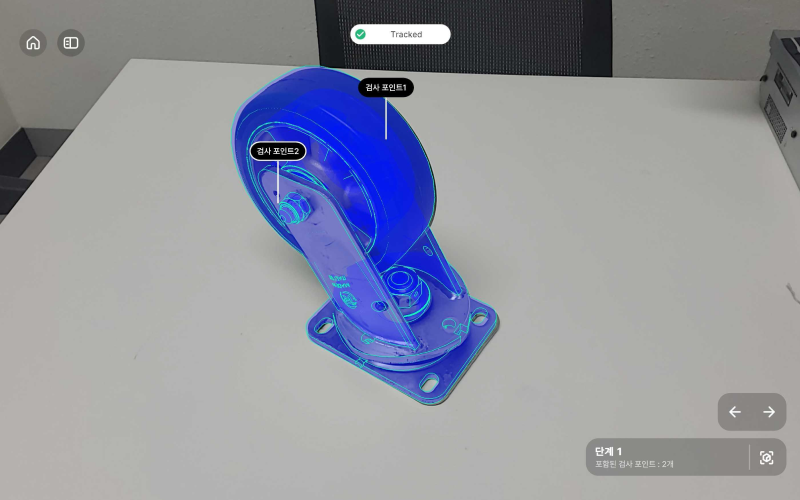

Fast and Intuitive Quality Inspection

With precise AR overlay technology,

you can immediately check deviations between 3D design data and actual objects.

This enables quick and highly accurate quality inspections.

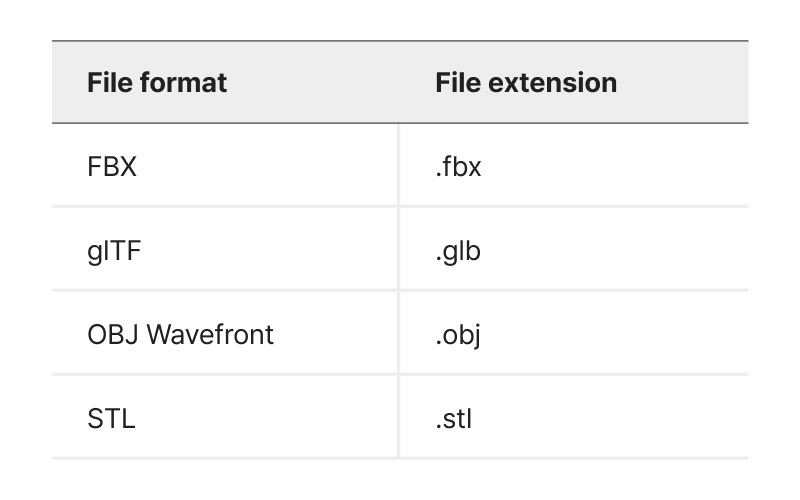

3D File Optimization and Lightweight Processing

Supports the four most popular 3D file formats (FBX, GLTF, OBJ, STL).

Through lightweight processing, it enables quick matching and smoother quality inspections.

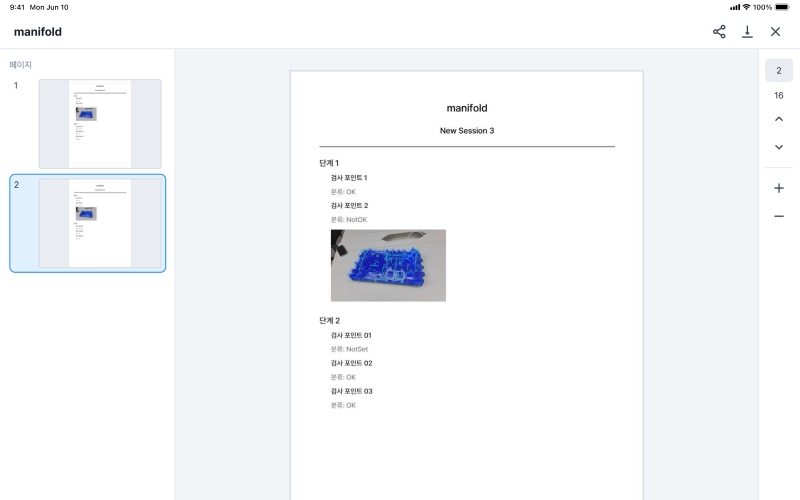

From Inspection to Report at Once

Inspection results can be recorded and documented through image capture, drawings, and notes.

The finalized report can be exported in PDF, XLS, or CSV formats, making it easy to share and manage.

-

![]()

In the production line, by enabling real-time data checks and rapid problem response,

it improves the efficiency and stability of manufacturing processes.

-

![]()

At construction sites, AR technology enables

intuitive visualization of the differences between design and actual construction.

-

![]()

By overlaying 3D design information onto the product,

you can visually identify discrepancies between the design and the actual build.

FAQs

Q. What kind of industry can use INSPECT?

A. INSPECT is applicable across various manufacturing and equipment industries involving human production and assembly.

It supports real-time inspections based on complex 3D design files,

making it suitable for any industry that requires precise quality control.

Q. Do you need special equipment to use INSPECT?

A. No. All you need is a tablet PC to view the model and a PC to optimize the 3D model.

Without requiring expensive additional equipment, inspections can be performed using 3D design files and AR technology.

Q. Isn’t the initial introduction cost burdensome?

A. Not at all. INSPECT is offered as a subscription service, which significantly reduces the initial introduction cost.

It also includes continuous updates and maintenance services, minimizing additional cost burdens.

Q. How much improvement in efficiency can be expected after introducing INSPECT?

A. Compared to traditional 2D drawing-based inspections, INSPECT significantly shortens inspection time.

It also improves error detection accuracy, leading to higher productivity and a lower defect rate.