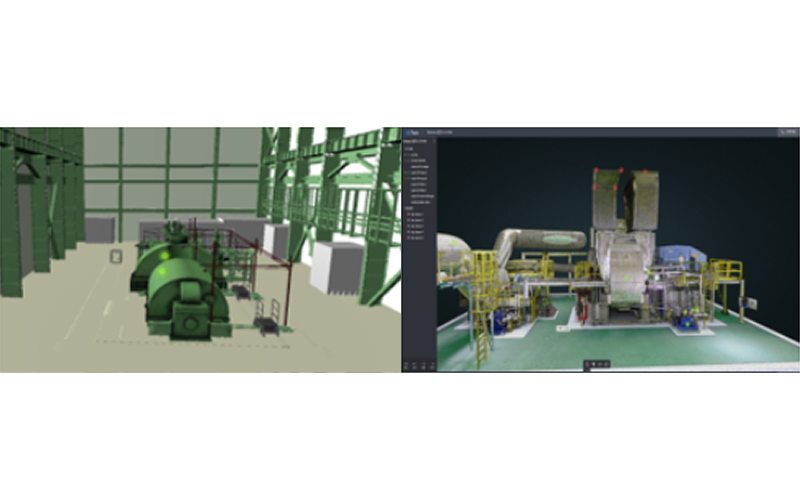

Environmental Digitization in Multiple Ways

Through panoramic images, point cloud data, and 3D models, environments are digitized in diverse ways to enable precise and comprehensive management.

This allows real-world spaces to be replicated virtually, supporting accurate analysis and efficient simulations

Fast and Accurate Construction – Point Cloud Technology

With point cloud technology, a digital twin environment can be built faster and more precisely than traditional 3D modeling.

It captures and reproduces detailed site data efficiently, enabling quicker and more accurate virtual space management.

Expansion of Functions through Robot Integration

Robots can be used to periodically collect existing or new spatial information and enable the setup of patrol inspections.

This enhances automation and boosts the efficiency of on-site management.

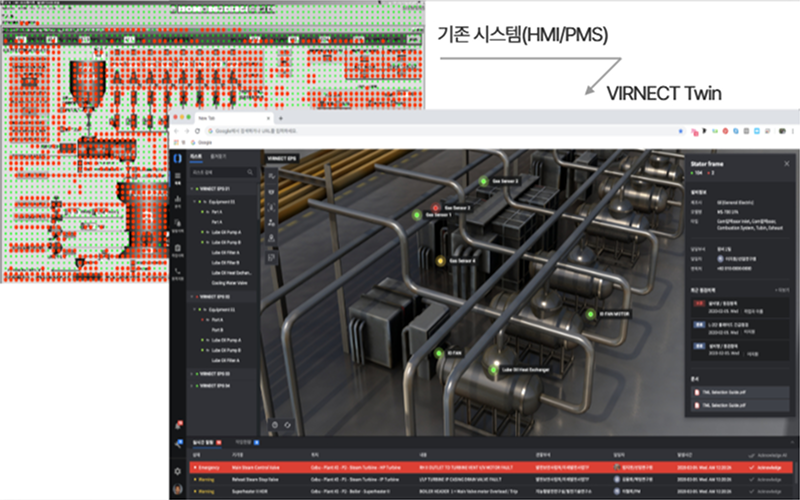

Integration with Existing Management Systems

By linking with existing management systems, you can easily access the digital twin environment.

This connection allows for efficient data checks and alarm reporting, enhancing the stability and reliability of operations.

Emergency Response Scenario Inspection

Depending on the emergency situation, you can diagnose the status of equipment and facilities and perform inspection simulations.

This ensures fast and systematic responses even in critical conditions.

Workers' Safety Management

By utilizing sensor information and enabling remote collaboration with field workers, safety measures and facility information can be managed efficiently and reliably.

This ensures worker protection and strengthens the stability of on-site operations.

-

![]()

Through real-time facility monitoring, maintenance history management, and resource optimization,

the productivity and efficiency of manufacturing processes are significantly improved.

-

![]()

By creating a digital twin through 3D scanning on-site,

it becomes easier to manage safety while supporting efficient process management and simulation.

-

![]()

In energy facilities such as power plants, real-time data integration enables remote monitoring and supports preventive measures before issues occur.

-

![]()

By optimizing the logistics system and enabling real-time monitoring of on-site operators’ location and status,

it provides a safer and more efficient working environment.

FAQs

Q. What is VIRNECT Twin?

A. VIRNECT Twin is a digital twin solution that replicates the real world digitally,

enhancing safety and efficiency through real-time data linkage, monitoring, and simulation.

Q. Which industries can VIRNECT Twin be used in?

A. VIRNECT Twin can be applied across various industries, including manufacturing, energy, construction, oil & chemistry, and logistics & warehouse.

It is particularly effective for safety management and equipment monitoring.

Q. What is the main function of VIRNECT Twin?

A. It enables real-time data monitoring, high-precision 3D scanning, predictive maintenance, safety enhancement, and AR/VR-based simulation.

Q. How does VIRNECT Twin help with safety management?

A. By enabling worker position tracking, risk detection sensor integration, and remote monitoring, it helps prevent accidents and ensures quick response when issues arise.

Q. Is it possible to integrate with existing systems?

A. Yes. VIRNECT Twin can be linked with existing systems such as HMI and PMS,allowing for integrated facility status management.